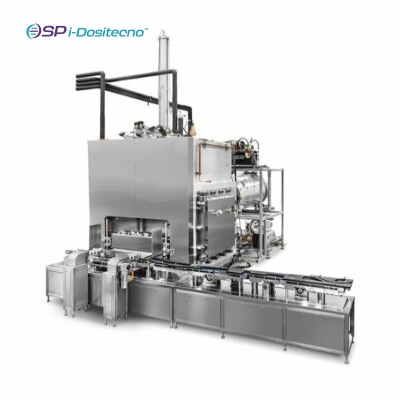

SP i-Dositecno Versa-Line Pharmaceutical Filling Equipment

SP’s modular Versa-Line fill-finish system and Line of Sight™ freeze dryer tools and technologies provide a customizable solution using quick delivery standard modules to their customers. With small scale and efficient design principles that adhere to cGMP quality guidelines, the SP fill-finish range specializes in low to medium speed applications.

Features & Benefits

Vial Washer

Small footprint, Spray manifold instead of needles, 3 log particle reduction, Reduced water usage, Servo driven operation with fewer moving parts, Easy and quick change over

Vial Sterilization and Depyrogenation Tunnel

3 log / 6 log reduction of endotoxin, Automatic Air Pressure Balancing, Dynamic sealing at the filter face, Monitor and record particle counts during the batch run in all zones, Sterilization of the cool zone

Vial Filling and Stoppering Machine

Filling System – Peristaltic Pump / Rotary Piston Pump / Mass Flow Meter, In process check weighing, Fully servo driven machine, Nitrogen purging, Suitable for Open RABS / Closed RABS / Isolator

Lyo Auto Loader and Unloader

Uses ”push-push” technology, Simple servo drive mechanisms, Pusher in rear of dryer unloads at end of cycle, Ambidextrous – can supply vials to / receive from Left or Right

Freeze Dryer

Capacity from 0.5 m2 to 80 m2, Quality by Design, ControLyo® Nucleation Technology, SMART Freeze-Drying™ Technology, Line of Sight PAT tools, Rotary Disc Isolation Valve, Tech transfer for scale up

Vial Cap Sealing Machine

Linear or Rotary Compact Design, Vertical force control during cap crimping, Torque control/strain gauge feedback for screw capping, Compatible with Open RABS / Closed RABS / Isolator

External Vial Washing Machine

Completely encapsulates the cap, High pressure water can be used, Air amplifiers for drying, Servo driven machine, Process is repeatable and easily validated for all change parts, Quick and easy changeover